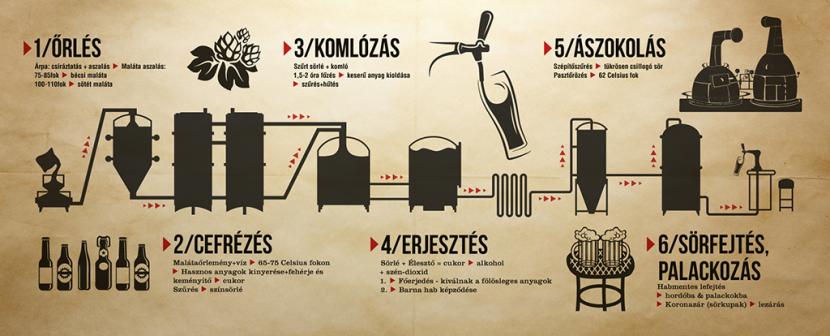

Milling

Malting is the first part of the brewing process, where barley grain is made ready for brewing. The grain must be milled so that, it should neither result too gross nor too fine, this is important to ensure the appropriate water coverage of the grains. The malt used for beer brewing is the sprouted and subsequently dried barley. During this process the fresh grain is immersed or steeped in water, than it is transferred to the malting or germination floor, which is usually a high temperature room, where the grains are spread out for a few days to sprout. During these few days the enzymes in the barley release the starches to make them water soluble.The next step is drying the barley to halt the progress when the sprouting begins. The final part of malting is kilning when the malt goes through a very high temperature drying in a kiln, with gradual temperature increase over several hours. Depending on the time and temperature of the kilning we receive different types of malts, the one dried between 75-85 °C is called the Vienna malts, another type is the darker Munich malt, which is dried in a temperature between 100-110 °C.

Mashing

Mashing converts the starches released during the malting stage into sugar that can be fermented. The milled grain is mixed with slowly heated water (up to 65-75 °C) in a large vessel known as the mash tun. During this stage, naturally occurring enzymes present in the malt convert the starches in the grain into sugars. This "conversion" is called saccharification. The result of the mashing process is a sugar rich liquid or "wort", which is then strained through the bottom of the mash tun in a process known as lautering. More hot water may be sprinkled on the grains to extract additional leftovers. What is left is the spent grain, which is not at all a useless by-product as it is a feed material of high nutritional value for animals.

Boiling

The wort is moved into a large tank known as a "copper" or kettle where it is boiled with hops. This stage is where many chemical and technical reactions take place, and where important decisions about the flavour, colour, and aroma of the beer are made. During the boiling process the materials responsible for bitterness are mostly extracted, what is left is what hops add as flavour, aroma and bitterness to the beer. That’s why we often call hops the spice of beers. At the end of the boil, the hopped wort settles to clarify in a vessel, where it must be brought down to fermentation temperatures as soon as possible. The biociding and preserving effects of alpha-acids prolong the warranty period of non-pasteurized products by sterilizing the wort. The cosy drowsy feeling we have after a few glasses of beer is also thanks to one of the ingredients of the hops, called lupulin which has a calming effect. For beer brewing we use non-fertilized seed cones from the female vine, viable seeds are undesirable, thus only female plants are grown in hop fields preventing pollination. Currently we not only use natural hops, but also pre-processed pellets. Some breweries work with hop extracts, a greenish-black mass, that already contains all the necessary ingredients, which make hops indispensable in creating a beer.

Fermenting

Fermentation takes place in stainless steel fermentation tanks, where yeast is added to the wort. Complete hygiene through proper cleaning procedures and careful protocol in the fermentation chambers is an absolute must, as the slightest contamination could lead to an infection. In this stage, sugars from the malt are converted into alcohol and carbon-dioxide. During this phase of process, the unwanted materials are extracted and dead yeast cells sink to the bottom of the fermentation vessel. Completing these steps, a brown foam is formed on the surface of the fermenting beer and the product can be called beer for the first time. However the majority of beer consumers would refuse this drink as it is still very rough and flavours hadn’t have time to abut.

Filtering

The beer is basically ready after fermenting, but trained eyes easily discover the cloudiness of the drink. There are different filtering methods (using Sheet (pad) filters or Kieselguhr filters) which can stabilize the beer’s flavour and give it the polished shine and brilliance. Not all the beer is filtered, these we call cask-conditioned beers, which are of great interest for gourmets. Some beers are pasteurized during filtering by heating it up to 62 °C for one or two minutes destroying the leftovers of microorganisms, thus warranty period prolongs considerably. However flavours, aromas, or even the scent of the beer can go lost. In Szent András Brewery, we draw all our beers fresh without pasteurizing to let the unique characteristics of our beers flourish.

Packaging

The beer must be drawn off foamless from a holding tank into sterilized casks or bottles. This process is carried out under high pressure, to avoid foaming it is necessary to inject CO2 into the casks and bottles. Finishing packaging we use the traditional crown caps to close the bottles.

Online beershops

Contact us

SZENT ANDRÁS BREWERY

5561 Békésszentandrás, Szent András utca 11.

Phone:

Rózsa Beerpub: +36-66-218-703,

Szent András Brewery: +36-20-925-9410

Order: +36-20-925-9410